Description

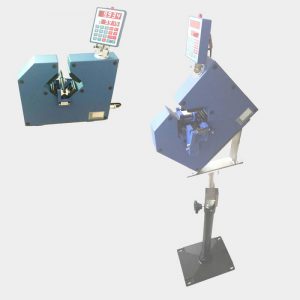

DDM-2025L Laser Diameter Micrometer with Display

Diameter Laser Gauge also called Optical Micrometer, Laser Detection, Diameter Detection, and Diameter Measurement.DDM series gauges are a new generation of Laser Diameter Gauge, A high-quality laser technology with a special non-contact and non-destructive measuring principle, for the measurement of the diameter the perfect system for quality control, process optimization, and stability.

With the DDM series laser diameter gauge, the diameter is calculated by diffraction analysis directly from the shadow image, this gauge features wide measuring range, high accuracy, long service life, and steady performance.

DDM 2025 laser monitor is a non-contact diameter measurement laser diameter gauge, it’s a laser diameter measuring device used for online diameter measurement, output diameter digital signal correspond to with cable diameter detected.

The cable diameter detection device is one kind of laser gauge for the diameter of cable or wire, it’s based on the laser diameter measurement technique, it’s one of the best devices of diameter measurer.

The DDM2025 comes with DSP-4A Monitor and controller, the DSP-4A monitor offering remote display and PI control signal output.

The Features of DDM series laser diameter gauge.

Very short exposure times

CCD image measuring technique with laser light sources

DSP data processing

Technical Parameters (Specifications)

| Model No. | DDM-2025L | DDM-2050L | DDM-2100L | DDM-25XY | DDM-50XY |

| Product Diameter | 0.1 ~25 mm | 0.1 ~48 mm | 0.5 ~95 mm | 0.1 ~25 mm | 0.1 ~48 mm |

| Accuracy | ± 2 μm | ± 2 μm | ± 5 μm | ± 2 μm | ± 2 μm |

| Exposure Time | 200 μS | 200 μS | 200 μS | 200 μS | 200 μS |

| Measuring Rate | 600 measurements/sec/axis | 600 measurements/sec/axis | 600 measurements/sec/axis | 600 measurements/sec/axis | 600 measurements/sec/axis |

| Interfaces | RS-485 | RS-485 | RS-485 | RS-485 | RS-485 |

| Power Supply | AC220V±10% , 50/60 Hz, 15 VA | AC220V±10% , 50/60 Hz, 15 VA | AC220V±10% , 50/60 Hz, 15 VA | AC220V±10% , 50/60 Hz, 15 VA | AC220V±10% , 50/60 Hz, 15 VA |

| Dimensions | 408 x 180 x 82 mm | 408 x 180 x 82 mm | 504 x 203 x85 mm | 355 x 330 x 82 mm | 355 x 330 x 82 mm |

Application and Features

DDM series laser diameter gauge is used for online diameter measurement for electric wire and cable, optic fiber cable, tubes, and wires. Typical applications: Measurement of the outer diameter of fine wire, Outer diameter lump, and neck down detection at ultra high speed, Outer diameter measurement in harsh environments.All digital image process technique and dedicated ultra-large-scale integrated circuit, which ensure high stability, compact size, and low power consumption.

RS-485 communication interface which makes the controller to be connected easily to an industrial computer, PLC and touch panel.

Mouthing position

DDM series laser diameter gauge can be mounted before or after the cooling trough. When it is mounted before the cooling trough, an optimized controlling effect may be obtained through in-time feedback due to the proximity of the measuring head to the extruder. But at this time the plastic coating is not cured, so the set nominal value must be accordingly. When it is mounted after the cooling trough, the measured value is the real diameter of the wire or cable. But the controlling effect is not so good because of the large control lag. Be sure to blow dry the tested wire or cable, otherwise, the measuring precision will be affected by the water coating around the wire or cable.

In practical using, the nominal value shall be increased appropriately according to the water content of the test object.

Check out the link below for the Application solutions.

Laser Gauge Diameter Measurer Application in cable production line