Description

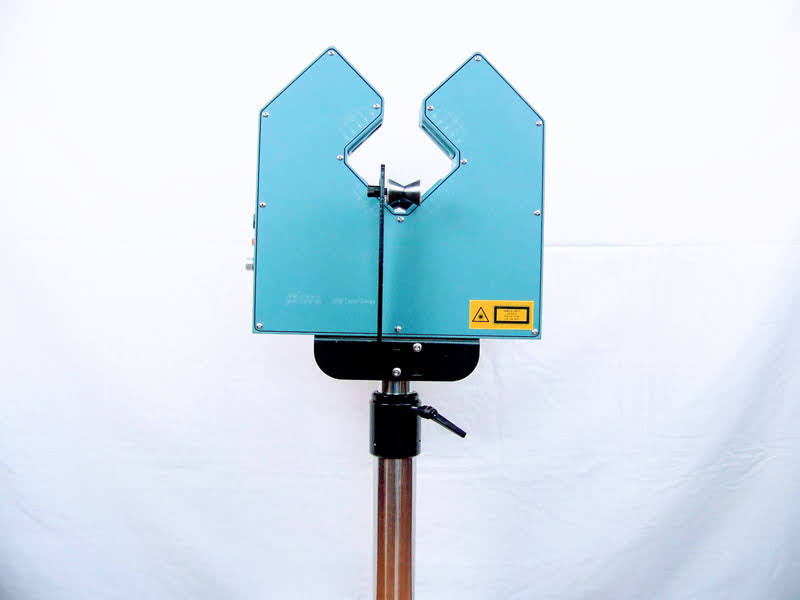

LDM-60XY Non-contact 2 Axis Diameter Laser Scanning Gauge

LDM-50XY is a double axis high-accuracy installment that uses the laser scan to carry on the non-contacts on-line measurement. It is mainly used in measuring the outer diameter and adjusting the extruder screw or traction speed, to control the outside diameter. It is applicable to measure and control the diameter of metal wires, glass, pipes, wire, and cable, etc.

The gauge applications include:

- Optical Fiber

- Wire

- Cable

- Glass Fiber

Technical Parameters (Specifications)

| Model No. | LDM-50XY | LDM-60XY |

| Axis | X and Y, Double Axis | X and Y, Double Axis |

| Measurement Type | Laser scanning | Laser scanning |

| Measuring Range | 0.2 ~45 mm | 0.2 ~55 mm |

| Accuracy | 0.002mm | 0.002mm |

| Repeatability | 0.5 μm | 0.5 μm |

| Exposure Time | 200 μS | 200 μS |

| Measuring Rate | 600 measurements/sec/axis | 600 measurements/sec/axis |

| Interfaces | RS-485 / Modbus (option) | RS-485 / Modbus (option) |

| Power Supply | AC220V±10 %, 50/60 Hz, 30 VA | AC220V±10 %, 50/60 Hz, 30 VA |

| Dimensions | 420*400*85mm (Gauge) 350*200*(700-1000)mm (Stand) 900-1200mm (Height of central measuring position) | 380*380*60mm (Gauge) 350*200*(700-1000)mm (Stand) 900-1200mm (Height of central measuring position) |

Application

One basic LDM-50XY measurement tool is composed of laser gauge and remote controller, it is able to be connected with different types of remote display.

The remote controller is mainly used for automatic control, which obtains measured data from the measurement gauge. PID signal comes out through the comparison between measured diameter

with a preset diameter and controls traction speed thereby controls wire diameter. In addition, a remote controller has a full-function operation panel and standard Serial I/O which communicates with PC

and PLC and supports diameter monitor software.

Laser gauge equals to a high-precision diameter sensor which not only measures online in real-time but also boosts strong data communication function.

For some occasion requiring only diameter measure, the laser gauge with the operating panel is competent for diameter measurement, display, and over-deviation alarm.

For some occasion not only requiring diameter measure but also automatic control, the solution includes a remote controller and laser gauge, which communicates with the former via serial I/O.

Measuring principle

A high-precision laser scanning system and embed digital processing electronics are embedded in the measurement gauge. The signal of diameter processed by scanning system, it is converted to digital signal firstly, and then comes out with real diameter and related data through a series of operation.

Leaser scanning data processing

The laser beam irradiates to the rotating prism and after reflection and through lens 1, it becomes a parallel beam. The parallel beam converges to the receiving component through lens 2. When placing EUT on the focal plane (FP) of lens 1, part of lights are shadowed, thus becomes electrical signal on receiving component and then comes out diameter and a serial of related signals after processing by measurement gauge.

Leaser scanning measuring principle

Leaser scanning measuring principle

The communication interface of the measurement gauge contains one serial I/O, it transfers measured data to a peripheral device (e.g. remote controller, PC, and PLC, etc.) through the serial I/O and to remote controls and displays through data channels.

Laser scanning gauge connecting to PC and PLC